Cutting

SMT

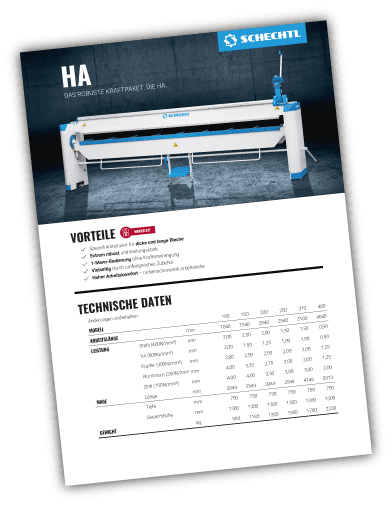

Precise cutting quality – even with thicker sheet metal

High-quality, durable shear blades

Optimum adjustment to production processes

High degree of flexibility in the production process through a wide range of variants

Automatic hold-down unit with slip-proof hard rubber insert holds the sheet firmly in position